Copyright©2020 Wuxi Gemei Lighting Electric Co., LTD. All rights reserved.Site Map|Privacy Policy

With the development and progress of science and technology, there are more and more LED lamps in the market, with different styles and quality.

When purchasing LED lamps, we can refer to the following five factors to select the appropriate lamps.

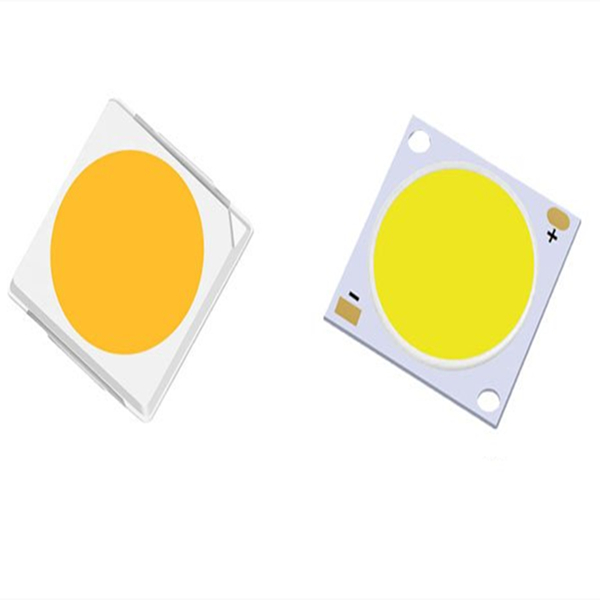

1. LED chip

Among the LED chip models, 2835 refers to the LED with the package size of 3.5 * 2.8mm, 5050 refers to the LED package size of 5.0 * 5.0mm, and 5730 also refers to the LED package size of 5.7 * 3.0mm. Under the same technical conditions, the larger the volume of the general package, the higher the price and the better the performance.

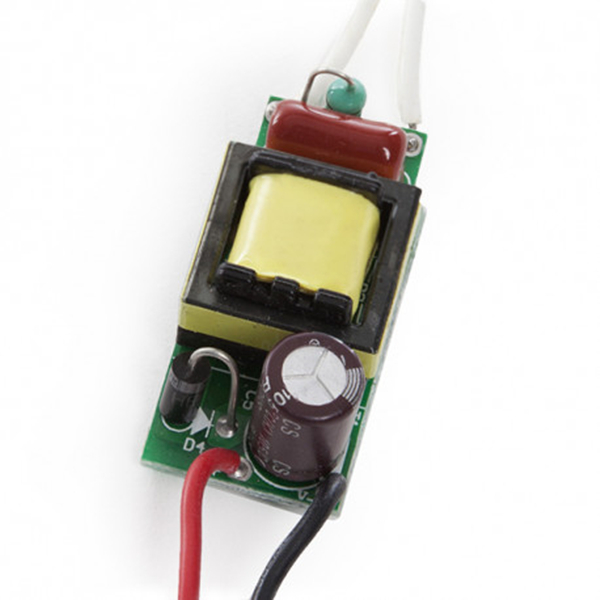

2. Driver

LED lamps should preferably be driven by constant current. To judge whether the lamp is a constant current power supply, you can use the mobile phone camera to aim at the light source. If there is no stroboscopic light source on the mobile phone screen, it means that the lamp is a constant current source, otherwise it is not; Judging the quality of the driving power supply, you can also listen to the working sound of LED lamps in a silent environment. If you can obviously hear the working sound of lamps, it indicates that the power supply of lamps is not very good, and there may be Jerry built electronic components.

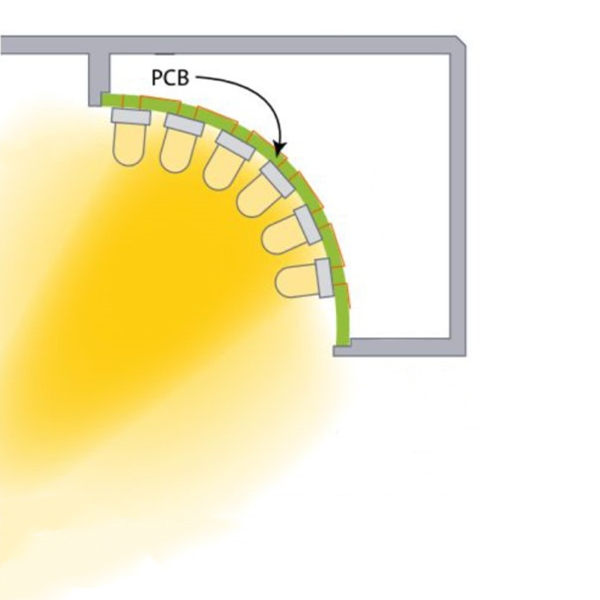

3. Light source circuit board

The most fatal weakness of LED is heat dissipation. If the heat cannot be dissipated at the first time, it is easy to affect its service life. The circuit substrate is preferably made of aluminum, because among the existing PCB materials, aluminum has the highest heat dissipation coefficient and the best heat dissipation effect, while fiberglass board and paperboard can not meet the heat dissipation effect required by LED. In addition, the light source of LED lamp circuit board should be designed in parallel, because even if one lamp bead is burned out, the whole lamp can still be lit normally.

4. Heat dissipation

LED is sensitive to temperature. It is best to use metal products for the chassis of fixed light source. Generally, iron chassis is common for ceiling lamps, because the heat transfer between metals is the fastest, and the heat on the substrate can be quickly dissipated through the iron plate. When choosing a smaller light source such as downlight and bulb, you can directly see the appearance of the radiator. The blade shape aluminum radiator is the best, and the thicker the better. Consumers are not recommended to buy plastic shell or no radiator. Secondly, heat conducting silicone grease shall be used for seamless bonding between the radiator and the aluminum substrate, so as to ensure that the LED luminous heat can be emitted in time.

5. Luminous effect

The higher the light transmittance of the lampshade, the better. The best material is acrylic PMMA (smooth surface), followed by PPV and PPR (poor light transmittance) and the worst is PC (rough surface). If it can't be seen from the surface at the time of purchase, multiple lamps can be lit at the same time to see whether the light transmittance of the mask is uniform. The more uniform and natural the light is, the better.